roll forming machine design pdf

A roll forming line can typically be divided into four major parts. Fed from a continuous coil.

Steel Roll Forming Machine Suspended Ceiling Systems Ceiling System Roll Forming

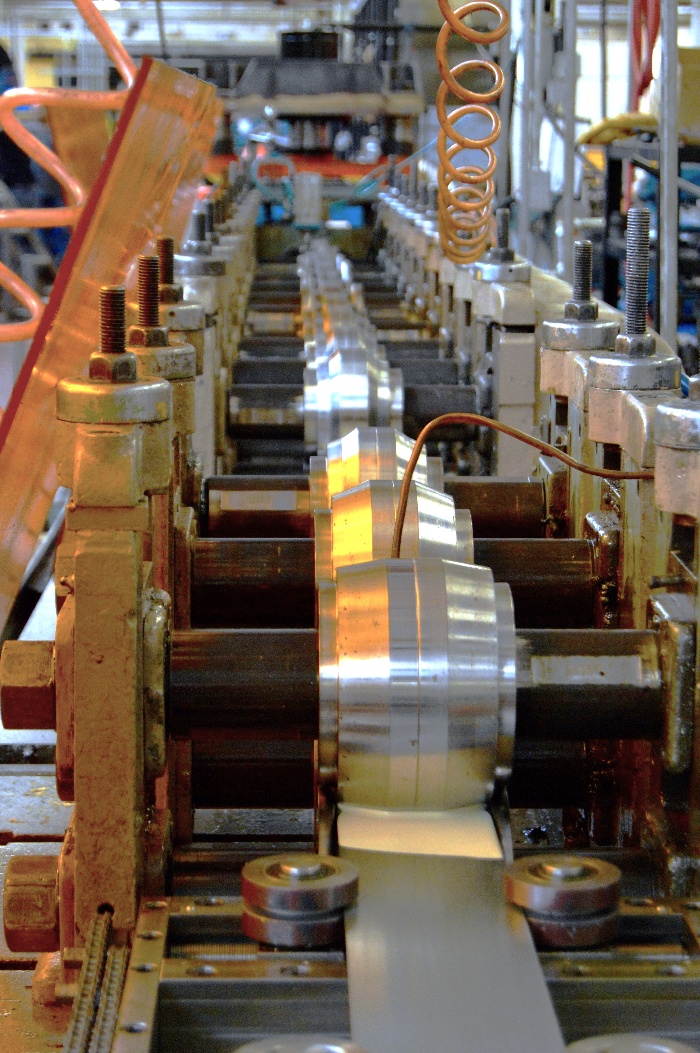

Rollform Design Software 1 Rollforming Rollforming is a continuous bending operation in which sheet or strip metal is gradually formed in tandem sets of rollers until the desired cross-sectional configuration is obtained.

. This machine works on simple kinematic system instead of complicated design. Download full-text PDF Read full-text References 9 Abstract In order to make reconstruction of the roll forming machine is necessary to define the. Calculate the estimated strip width.

Roll Forming Machine is a processing machine that passes rolled steel or other long strips of metal through a series of Hardened Steel Rollers which are controlled using a pre-set PLC code to achieve a specific processing operation on the sheet metal at each station to produce a specific metal partIt is characterised by high progress high speed low scrap and one-off. They are as follows. For fewer defects in bending take big roller diameter 5 times pipe diameter and small roller diameter 3 times pipe diameter.

Roll forming is ideal for producing parts with long lengths or in large quantities. Or in other word with the least amount of rollers. A rigid forming roller a free.

Roll Forming Machine design aim is to form the desired sections repeatedly within a specified tolerance. Hence aim of our project to develop and design a portable sheet bending machine which is useful to bend a sheet into cone and cylinder shape. The overall conclusions of the present work are that today it is possible to successfully develop profiles of complex geometries 3D roll forming in high strength steels and that finite element simulation can be a useful tool in the design of the roll forming process.

This condition can result in panel buckling. Produce a bend progression or flower pattern. Material entry section roll forming machine cutoff press and exit section.

Removal of the buckled panel from the line is time-consuming and may result in damage to the cutoff die or in extreme cases to the roll tooling. Develop a cross-sectional drawing. 22 Design of Rollers The diameter of pipe Dp is 19 mm 34 inch.

How to Design for Roll Forming IN THIS VIDEO YOU GET MORE INFORMATION ABOUTroll forming machine design roll forming roller design Make roll forming machin. Lay out and design the roll tooling around the flower. Roll forming machine design Line speeds die speeds and die clearances must closely establish and monitor to prevent blade drag.

This paper presents the design construction and evaluation of a sheet metal rolling machine for small-scale en terprises. 4 rollers 3 rollers and 2 rollers each of which has as different advantages according to the desired specifications of the output plate. At the section of a roll forming line material may be fed in sheet form transferred directly from another operation such as piercing or more monly.

The machine consists of three rollers. This machine can bend up-to 4-5mm thickness of. Sheet Metal Rolling Machine is classified into two types based on the arrangement of the rollers.

Roll Forming Machine design aim is to form the desired sections repeatedly within a specified tolerance. Figure 1 On the cross-sectional drawing youll need to determine the part material and mill specifications and tolerances. Iv The doctoral project has resulted in following.

Roll forming is ideal for producing parts with long lengths or in large quantities. Machine concept and design has an important influence on the geometryquality of 3d roll formed profiles for the process design and the machine design new simulation strategies need to be applied - combining fea simulations multi-body dynamic simulations cad programs and kinematic simulations for workspace and collision investigations data m. Figure 21 Roller dimensions So Big Roller diameter 95 mm Small Roller diameter 57 mm.

There are 3 main processes. Sets of rolls known as roll stations Shape the metal in a series Of progressive Stages until the desired Cross-sectional is obtained Because Of the in which the bending takes place there is little Or no cross-sectional area Of the Draw a line. To quick will distort the product while Too slow will make the machine uneconomical.

Using the least amount of steps. Wide flat nonformed components will create different difficulties throughout roll forming. It reduces human effort and also requires less skill to operate this machine.

Pinch type machine 2. The material selected for the roller is Case hardened steel. If just roll forming one side of the product and also the rest of the strip could be a wide flat part then a small pressure there on flat part will make.

In roll forming machine roller design many ways to reduce or eliminate edge or center waviness. View More Roller Design Process. Pyramidal type machine This machine is of pinch type here only the top roll serves as a driven bottom roller are idler and rotates on friction with the work metal blank.

Cu Channel Roll Forming Machine Size Changeable An Immersive Guide By Roll Forming Machine

Roll Forming Custom Roll Forming Process Roller Die

Metal Forming Processes Techniques Industries Use Cases

Customized Steel Tube Production Machine Roll Forming Geometric Logo Metal Forming

Pin On Construction Material Roll Forming Machine

Electric Enclosure Box Roll Forming Machine Metal Roll Forming Machine For Fire Damper Blade Roll Forming Dog Car Seat Cover Machine Service

Pin On Steel Pipe Process Machine

Steel Roll Forming Machine Roll Forming Wall Boxes Machine Service

The Function Of Color Plate Cold Roll Forming Machine Roll Forming Cylinder Cold Rolled

Fire Damper Making Machine Roll Forming Making Machine Signage Design

Ms D Pipe Roll Forming Machine Production Line

Metal Roll Forming Machine Production Line Roll Forming New Things To Learn Metal Forming

Cable Tray Roll Forming Machine Factory Cable Tray Roll Forming Tray

Making Roll Forming Machine Roll Forming Machine Process From Design Till Produce Youtube Roll Forming Design Rolls

Roll Forming Machine Design Roll Former Design Believe Industry Machine Design Roll Forming Design

Roll Forming Machine Plans Drawings Dxf Pdf Etsy Roll Forming Repair And Maintenance Plan Drawing

Cold Roll Forming Machine For Floor Deck Machine Design Metal Drawing Roll Forming

Fush Box Flush Mounting Switch Box Making Machine Making Machine Easy Food To Make Electric Box

Steel Roll Forming Machine Suspended Ceiling Systems Ceiling System Roll Forming